Improve collaboration, efficiency, and take control of your budget to make the most informed decisions.

900+

$120B+

$15B+

50

“Implementing Questica Budget has saved us over $85,000 in productivity savings annually.”

Budget

Budget

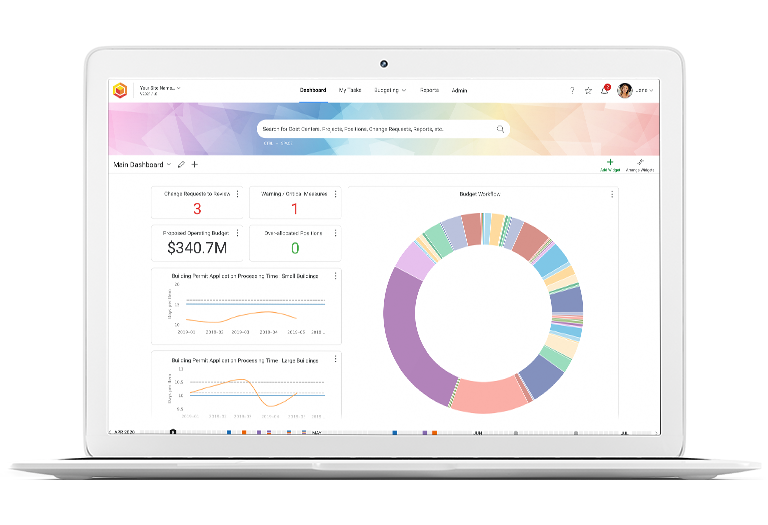

Better, faster andeasier budgeting.

Transform your budgeting cycle from end-to-end with a single source of truth. Enable data-driven budgeting and decision-making, while increasing data accuracy, saving time and improving transparency. Run this year’s operating, salary and capital budgets with accuracy and efficiency with Questica Budget, our comprehensive multi-user budgeting software solution.

Tour Budget

Performance

Performance

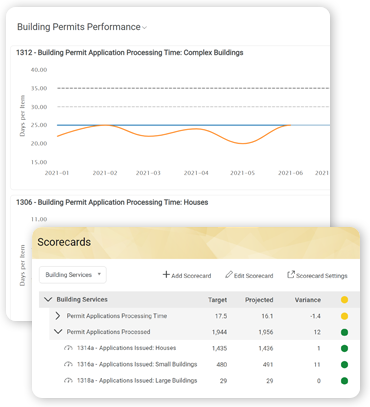

Establish performance metrics and set the standard for your budget.

Questica Budget’s Performance system of programs, measures, and scorecards allows you to track an unlimited number of budget and non-budget performance indicators (KPI’s) to measure financial and non-financial goals.

Tour Performance OpenBook

OpenBook

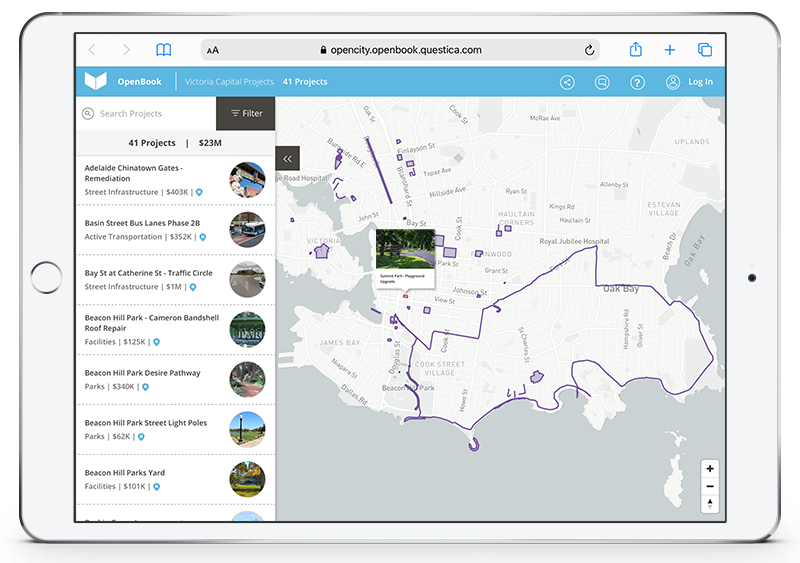

Communicate your financials in an open, transparent, and accountable way.

Use Questica’s OpenBook module to visually display your budget data in easy-to-understand and searchable charts, graphs, and tables. Increase stakeholder engagement by using OpenBook with leading budget simulation tools like Balancing Act.

Tour Openbook

Request a Demo Today!

See our budgeting software in action. Fill in your info and our team will reach out to determine how we can help you increase efficiencies for your budgeting process.